Mastering the Machine: Identifying the Core Components That Power Robotics

Although robots or other automation consists of hundreds of parts assembled together, the critical components used in Robotics and Automation equipment can be categorized into four main functional areas: the brain, the senses, the muscles, and the tools.

The Control System (The Brain)

This is the central processing unit that executes programs, interprets sensor data, and sends commands,

Programmable Logic Controllers (PLCs): Specialized industrial computers used to control and automate electromechanical processes, they are highly reliable and handle multiple inputs and outputs.

Controllers/CPUs: The computer and software package that serve as the main processing unit for robots, this interprets complex movements and coordinates all components.

Software and Programming: The logic that defines the robot’s or automation system’s behaviour, including path planning, safety protocols, and complex algorithms (sometimes utilizing AI or Machine Learning).

Human-Machine Interfaces (HMIs): Devices or software (like touchscreens) that allow operators to monitor and interact with the automation system.

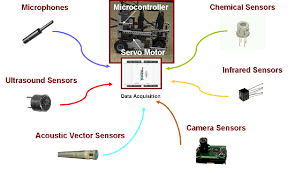

Sensors and Feedback Devices (The Senses)

These components gather information about the environment and the system’s internal state, providing the necessary feedback for precise operation and safety.

Sensors: Devices that measure physical parameters and convert them into electrical signals, types include:

Proximity/Range Sensors: Detect the presence or distance of nearby objects (e.g., ultrasonic, infrared, LIDAR).

Vision Systems (Cameras): Enable the robot to “see” and interpret visual data for object recognition, quality inspection, and navigation.

Force/Torque Sensors: Measure applied forces, crucial for tasks requiring delicate handling or collaboration with humans (collaborative robots or “cobots”).

Environmental Sensors: Measure temperature, pressure, light, etc., relevant to the task or operating conditions.

Encoders: Feedback devices that monitor the rotational position and speed of motors and joints, essential for accurate motion controls.

Actuators and Drives (The Muscles)

These components convert electrical energy or fluid power into physical motion, allowing the robot or machine to move and perform work.

Actuators (Motors): Devices that generate motion with the most common types including –

Servo Motors: Offer precise control of angular position, velocity, and acceleration, typically paired with a servo drive (an electronic amplifier and control circuit) and are dominant in high-precision robotics.

Stepper Motors: Divide a full rotation into a number of steps, allowing for precise open-loop positioning without a separate sensor.

Pneumatic/Hydraulic Cylinders: Used in heavy-duty or simpler applications to generate linear or rotary motion using compressed air (pneumatic) or fluid (hydraulic).

Manipulator/Arm: The mechanical structure (links and joints) that provides the degrees of freedom (axes of movement) necessary to position the end effector.

End Effectors and Power Supply (The Tools and Lifeline)

These are the parts that directly interact with the work environment and provide the necessary operating energy.

End Effectors (End-of-Arm Tooling – EOAT): The device or tool attached to the end of the robotic arm to perform a specific task.

Grippers: Mechanical or vacuum devices used for grasping and manipulating objects.

Specialized Tools: Welding torches, painting sprayers, drills, cutters, and assembly tools.

The Results – A Complete Assembly Line